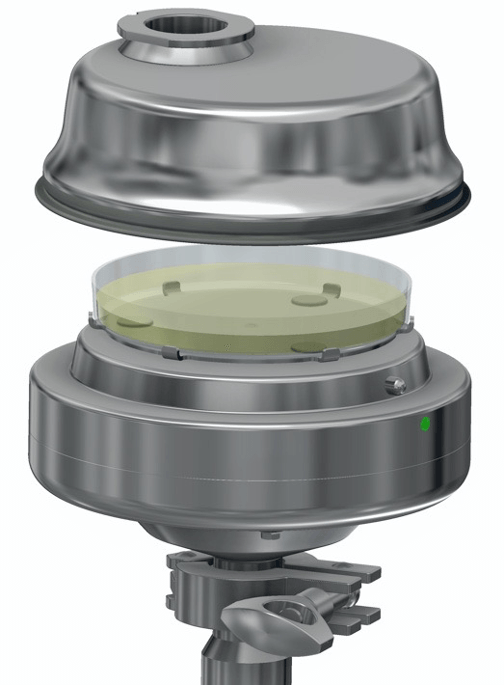

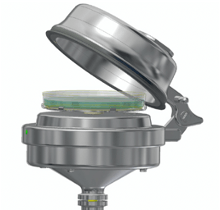

The ISO-90 Monitoring Head contains all controls and mechanisms necessary to rotate the agar plate throughout the monitoring period. The head does not contain a pump but internal flow sensors are used to enable the head to send signals to a vacuum source to control the air flow very accurately.

The head is 122mm diameter and 107mm from the clamp flange to the top of the inlet.

There are a number of different approaches using active air samplers to meet Annex 1 compliance. The pharmaceutical industry use isolators, R.A.B.S., and others manufacture in cleanrooms. Some processes are highly automated and some more manual. Users also require flexibility to monitor for shorter periods at higher efficiency, whilst others want to monitor for the longest period possible with minimal human intervention.

These different requirements would normally necessitate different instruments but the ISO-90 head inlet can be configured to optimise the sampling parameters. There is a default configuration that allows 4 hours monitoring onto a single agar plate with a flow rate of 15 litres per minute at a d50 of 0.53μ.

Alternative inlet sizes are available – please ask our representative for more details.

A button located on the head unit is available so the operator can simply load a plate and press the button to start, pause or stop a run.

The head can be supplied in a number of deployment formats to suit the application and with an increase in the use of robots within isolators, the chamber can also be supplied with robot compatible manipulation features.

Download the ImpactAir Product Guide

Contact us about ImpactAir-90

and ISO-90